Researchers develop “designer yeast” as palm oil alternative

Key takeaways

- Researchers in Frankfurt and Dalian have engineered yeast enzymes to produce lab-made fatty acids that mimic those found in palm and coconut oil.

- The technology provides a lower-impact alternative to palm oil, addressing deforestation and biodiversity loss associated with conventional sourcing.

- Scaling and industry partnerships will determine whether synthetic fatty acids can compete with palm oil on cost and supply.

A research team at Goethe University, Germany, has developed a new method to create sustainable oils in cosmetics. The group conducted key research on the production of fatty acids that mimic those found in palm and coconut oil by reprogramming yeast enzymes. Lead researcher Martin Grininger has called for collaboration with an industry partner to amalgamate the science with the market.

Meanwhile, a subsequent breakthrough by professor Yongjin Zhou’s research group — in collaboration with Grininger — at the Dalian Institute of Chemical Physics, who successfully manipulated the length of the carbon chain, has provided a lab-made alternative to palm and coconut oil.

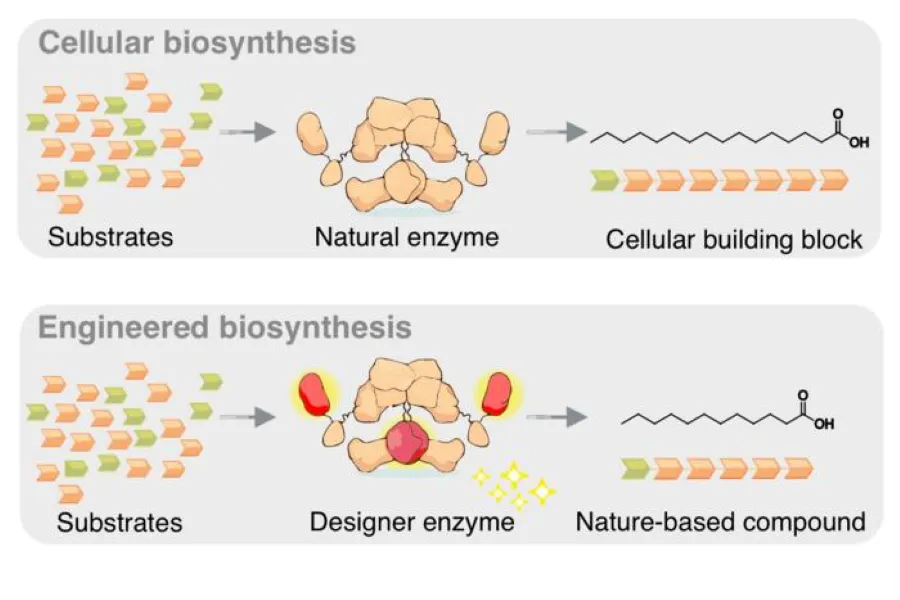

The research centered on fatty acid synthase (FAS), a type of molecular assembly line that builds fatty acids in all living organisms. The report from Goethe University explains that while the FAS enzymes typically produce a 16-carbon fatty acid, the industry primarily requires shorter variants with six to 14 carbon atoms.

The research postulated that adjusting the chain length could be achieved by modifying the two subunits responsible for the length regulation of the enzymes. Grininger’s previous research identified ketosynthase and thioesterase as the two length-regulating subunits. The former elongates the chain by two carbon atoms while the latter cuts off the complete chain as a fatty acid.

Through engineering the proteins associated with the subunits, the team was able to alter the FAS enzymes to produce shorter carbon chains, mimicking the C12 fatty acid structure naturally found only in palm kernels or coconuts. In doing so, they would be altering yeast enzymes to be used as substitute fatty acids for environmentally strenuous raw materials.

Grininger states that “true understanding begins when you can change or customize a phenomenon.”

The Dalian Institute of Chemical Physics achieved the breakthrough by producing yeast strains with fatty acids containing 12 carbon atoms using the protein engineering method.

A case for synthetics

There is an increasing discourse around natural versus sustainable cosmetic ingredients. The term natural often has an association with mindful consumerism and sustainability. ast enzymes are engineered to mimic palm oil fatty acids.

ast enzymes are engineered to mimic palm oil fatty acids.

However, in the case of fatty acids like palm oil, the water- and land-intensive requirements of sourcing the raw materials, combined with the demand for ingredients, can lead to vast deforestation and loss of biodiversity.

“Natural cosmetics can have significant negative environmental impacts, despite their eco-friendly image. A prominent case that has lost its natural, sustainable image is palm oil — widely used in soaps, lotions, and makeup,” Thomas Collier, CEO at Levur, told Personal Care Insights.

“An estimated forest area of 300 football fields is cleared every hour for palm plantations. Such land clearing destroys habitats of endangered species, such as orangutans and tigers, and releases massive carbon emissions.”

Australian start-up Levur is also working with yeast to create a lab-grown alternative to palm oil through fermentation.

Natural cosmetic oils often require an extractivist approach to the resources, making it unsustainable. Subsequently, more beauty companies are turning to lab-developed alternatives to climate-intensive natural ingredients.

Supply, demand, bureaucracy

Despite the growing portfolio of alternatives, the global palm oil market is projected to expand at a rate of approximately 0.8% per year over the coming years, according to the OECD-FAO Agricultural Outlook.

Many beauty companies continue to favor the use of palm oil in their products, primarily due to their established supply chains and the low financial costs of acquiring palm oil.

While regulatory measures are in the works to combat the structural entwinement of palm oil extraction and the chemical industries, their implementation is progressing at a slower pace than anticipated.

First announced in 2023, the EU Deforestation Regulation (EUDR) was meant to be integrated into law in late 2025. However, amendments formally adopted in December 2025 have pushed the implementation of the regulation to the end of 2026. The amendments were due to the readiness of businesses to adopt regulations and technical issues related to new information systems.  Lab-made fats offer an alternative to palm oil sourcing.

Lab-made fats offer an alternative to palm oil sourcing.

The EUDR aims to combat biodiversity loss and deforestation by removing products sourced from deforested land from EU markets. By banning or strictly restricting the import and sale of products linked to deforestation and supporting agroforestry, the EUDR provides a steady regulatory scaffolding as the EU beauty market moves away from palm oil and starts seeking substitutes.

Lab-developed alternatives to naturally sourced cosmetic oils offer a more sustainable solution that aligns with the incoming EU legislation. Regulations such as the EUDR promote more ethical sourcing practices, which push beauty ingredient innovation that may have otherwise been forgone.

Looking ahead

The Goethe University scientists say that whether their technology can alleviate palm oil issues depends on successful scaling up alongside industry partners.

“The scientific foundation has certainly been laid, and the lab still has many ideas to explore,” says the report, placing the ball in the court of industry representatives.

Both the German and Chinese laboratories have filed patents for their technologies. “On the Chinese side, Unilever was involved in this project. Our development has thus far taken place without industrial participation. However, we are striving for a collaboration with an industry partner to bring the technology into application,” says Grininger.